Not all plastics are created equal… and the same goes for recycled plastics. It’s important not to view “plastics” as a monolithic entity, as the term encompasses a wide range of materials, each with very different properties and uses.

A staggering seventy-five percent of plastics polluting the oceans first originated on land, found their way into waterways and were ultimately deposited into the oceans. While some of this pollution comes from deliberate littering, much originates via inadequate handling of post-consumer waste. According to UNESCO, about 100,000 marine mammals and one million seabirds are killed annually by plastics that end up in the ocean.

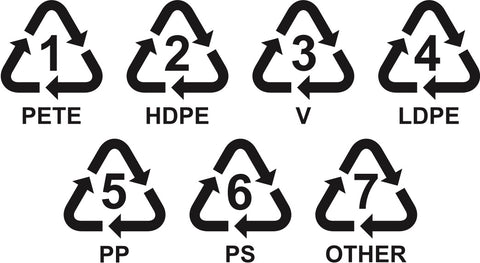

In the face of these environmental consequences, efforts to divert plastics from the waste stream to recycling and clarifying what can be easily recycled together are essential. To streamline this, The Society of the Plastics Industry, Inc. (SPI) introduced a coding system for resins in 1988 at the request of recyclers. These codes are used for classifying plastics into groups that can be recycled together.

At Oceanworks, we don’t play favorites… any plastic that can be recycled and diverted from the waste stream or our natural environment is worth our attention. But the products most commonly recycled—which also pose the biggest threat to our oceans, beaches, and waterways—are the ones we worry about most.

Despite the fact that so many plastics have the potential to be recycled, according to the United States Environmental Protection Agency, only 8.7% of the 35 million tons of plastic waste were recycled in 2018.

PETE (Recycling Code 1)

PETE (or PET) stands for Polyethylene Terephthalate and was first synthesized by scientists at Dupont Chemical in the 1940s. Since then, it has become an extremely common plastic used for soda bottles, water bottles, and other types of food packaging. Its transparency makes it a lightweight, durable substitute to replace glass and is highly desirable for these purposes.

PET is very easy to recycle and is usually reused for bottles or polyester fibers. According to PETRA, the PET Resin Association, approximately 31% of PET in the United States is recycled, compared with a more robust 52% recycling rate in Europe. It can be easily recycled and is the most recycled plastic globally today, but the demand for recycled PET still isn’t being met by existing recovery processes.

HDPE (Recycling Code 2)

HDPE stands for High-Density Polyethylene. The plastic is used most often for packaging; including but not limited to milk bottles, laundry detergent, hair care products, and cleaning supplies. It is harder and more resistant to physical and chemical damage than many other plastics. As a result, it can withstand extreme temperatures and contain a variety of chemical agents without fear of degradation.

When recycled, HDPE is typically reused for nonfood containers and crates. HDPE’s light weight, strength, and moisture barrier functionality make it ideal for products that must travel long distances to reach consumers. HDPE helps ensure those products arrive in good shape and with a lower transportation cost.

HDPE is 100% recyclable, typically done via a process of shredding, melting, and subsequent pelletization. As a result, HDPE’s recovery rate is second only to that of PET and commonly accepted at most recycling centers globally.

PVC or V (Recycling Code 3)

Polyvinyl Chloride uses the codes PVC or simply V. PVC is a hardy, strong, and diverse plastic that can be either rigid or elastic and is found in clear, white, and colored versions.

PVC is frequently found in building materials such as pipes, fittings, siding, and hoses due to its strength and durability in all types of weather conditions. It’s also suitable for cleaning and personal care product bottles due to its durability and lack of interaction with the chemicals commonly found in these products. PVC is also used for medical equipment, food packaging, and wire conduits.

Its manufacturing process can release dangerous chemicals and the chlorine in PVC is released when incinerated, creating dioxin, a heavy-duty environmental pollutant. This makes it doubly important to properly handle PVC waste and divert it into the recycling stream to avoid additional environmental pollution.

Unfortunately, PVC is not commonly recycled. When it does find a second life, it’s frequently used for similar applications as the virgin variety, such as for pipes and fittings and paneling. More recently, many synthetic timber and decking companies have introduced deck building materials made from recycled PVC. Other uses for recycled PVC include automotive uses such as mud flaps and floor mats, drainage and other types of mats, speed bumps, and shoes.

LDPE/LLDPE (Recycling Code 4)

Low-Density Polyethylene is a thinner, more flexible plastic commonly used for wrapping and packaging, including bubble wrap. LDPE is FDA-approved for food contact, has high heat resilience, and is a good match for applications using heat sealing. Film LDPE is frequently excluded from curbside recycling programs, however, but can often be recycled at grocery stores.

Rigid LDPE is used for things like bottles, caps, containers, and lids. LDPE can be used to protect products from chemicals and moisture during shipping without adding much additional weight.

It can be recycled into similar film products like shipping envelopes or garbage can liners, but rigid LDPE can be recycled into more heavy-duty products as well.

Linear Low-Density Polyethylene is used as a film wrap for food, prized by companies in that industry for its ability to delay food spoilage due to its resistance to tearing and puncturing. 55% of it is used for single-use purposes.

However, when recycled it has desirable properties for other purposes, including outdoor and mechanical applications since it’s more flexible and less brittle than other plastics.

PP (Recycling Code 5)

Polypropylene (PP) is found in clothing and ropes as well as tubs and bottles. Its rigidity, high melting point, and resistance to many chemical solvents accounts for its wide variety of uses in consumer products, including toys, storage items, and cleaning supply containers. In addition to its rigidity and the ability to withstand heat, PP also prevents moisture transmission. These factors make PP ideal for food packaging, particularly when the food is packaged while hot or destined to be microwaved by the consumer.

PP can be recycled into fibers and pellets, however, it is one of the least recycled plastics, despite being in high demand. PP degrades more rapidly than other plastics (after 20-30 years), but the microplastics and additives released during the process pose significant environmental threats.

PS (Recycling Code 6)

The PS for recycling code 6 stands for polystyrene, a plastic typically used for rigid purposes where its brittle nature does not pose a problem or for foam products. Most consumers encounter polystyrene in disposable plasticware such as glasses and cutlery, takeout food containers, insulated coffee cups ,as well as egg cartons and meat trays.

Polystyrene is collected via some community recycling programs and, when recycled, can find new life as insulation, packing materials, office supplies and equipment, coat hangers, and building materials such as light switches and air conditioning vents. Demand for polystyrene has declined year over year, in part because of challenges with recycling and some local ordinances banning its use in food service.

Recycled polystyrene can find new life as egg cartons, electronics casings, license plate frames, rulers, architectural moldings, and packaging.

OTHER (Recycling Code 7)

Recycling Code 7 is a catch-all designation used for other types of recyclable plastics, including polyamide (nylon), polycarbonate, acrylonitrile butadiene styrene, and thermoplastic elastomers. Because polycarbonate plastics contain Bisphenol A (BPA), there are significant concerns about that chemical leaching into food and drinks, which has caused it to fall out of favor for those applications.

Polycarbonate is easy to color and highly resistant to impact and used for shatter-resistant and bulletproof glass, as well as in consumer electronics. Although difficult to recycle, diverting this material from landfills and waterways is essential due to the many environmental impacts it has once it enters the waste stream. It does not degrade, and it releases many toxic elements into the environment over time, posing a major risk to sea life and the seafood humans eat.

Polycarbonate can be recycled, but it is typically through a chemical process versus traditional mechanical recycling.

Additionally, this #7 code is also—often confusingly—used on packaging that is compostable and made from biological-based polymers. Often compostable #7 plastics will also include “compostable” or “PLA” designations on the container to indicate that it is, indeed, compostable.

PA/Nylon

Polyamide (PA), commonly known as Nylon, is a class including several varieties, the most common being Nylon 6 and Nylon 6,6. Nylon is often categorized as an engineering plastic since its mechanical properties are superior to those of commodity plastics like the ones listed above. As such, Nylon is used for fishing nets, durable clothing, and can also be found in various applications within the automotive industry.

Nylon recycling requires significantly lower temperatures than most plastics, but it is prone to the release of contaminants. Therefore, the material must be thoroughly cleaned before it can be mechanically recycled. Though relatively uncommon, nylon recycling is increasing in popularity. Since fishing gear accounts for a significant portion of waterway plastic pollution, it’s important that nylon recycling be prioritized.

ABS

Acrylonitrile Butadiene Styrene is a strong, rigid, and shiny plastic. It’s used in electronics, automobiles, planes, helmets, golf clubs, and suitcases. It’s also the plastic used in Legos.

ABS can be recycled and injection molded for new purposes. ABS can be reused several times through cyclical use, melting, and re-molding. Though much of the world’s ABS is not recycled, the process is simple enough that it could be done by individual consumers (with the right equipment).

TPEs

Thermoplastic elastomers are a group of plastics, the most popular of which is thermoplastic polyurethane (TPU). TPU is sometimes called the bridge between rubbers and plastics. It is relatively hard but has just enough “give” that it can be used for applications that formerly relied on rubber. Compared to rubber, though, TPE offers the benefits of lower production costs and increased durability. It is a favorite for 3D printer applications and is commonly found in products like cell phone cases and sporting goods. Other TPEs offer more flexibility and smoother textures.

TPEs are recycled in one of two ways: mechanically or chemically. Mechanical processes include chopping or grinding down the virgin material so that it can be compression molded into a new product. Chemical recycling processes break the material down into its chemical constituents, which can then be used to create new raw materials, including new TPEs. Despite this, the recycling of TPEs is highly uncommon in most parts of the world.

Ready to see if there’s a market for your recycled ocean plastics or a nearby supplier of the certified recycled plastics you need for your manufacturing processes? Check out the Oceanworks Marketplace.